Why You Need A Titans Packaging Typhon Robotic Palletizer

The Solution To Your Palletizing Problems - Titans Packaging Typhon Robotic Palletizers

Why Your Business Needs a Titans Typhon Palletizing System Today

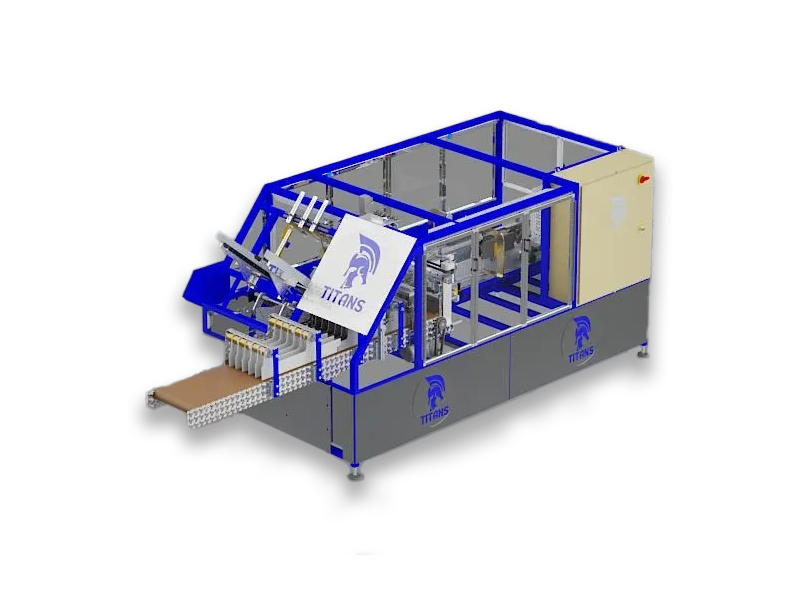

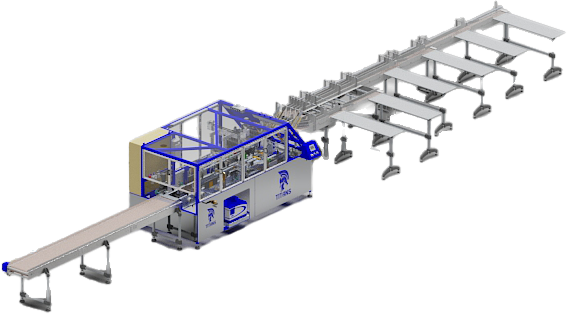

In modern manufacturing and packaging, speed, efficiency, and labor optimization are no longer optional—they’re essential. If your operation still relies on manual or outdated palletizing methods, you’re losing valuable time, money, and productivity every single day. That’s why leading manufacturers are choosing the Titans Typhon Robotic Palletizing System—a flexible, plug-and-play solution engineered for maximum uptime, quick deployment, and measurable ROI.

The Problems Titans Typhon Solves

- Labor Costs & Shortages

Hiring and retaining skilled labor for repetitive palletizing tasks is increasingly difficult—and costly. The Typhon palletizer eliminates the need for multiple manual laborers on the end of your line, freeing your workforce to focus on higher-value roles. - Inconsistent Stacking & Safety Risks

Manual palletizing often leads to uneven loads, increased damage rates, and higher worker injury risks. The Typhon system ensures perfectly repeatable stacking patterns every time, reducing product damage and improving workplace safety. - Slow, Inefficient Changeovers

Many palletizers require long changeovers when switching case sizes or patterns. The Titans Typhon offers built-in pattern generation software, allowing operators to adjust palletizing configurations in minutes without the need for outside technicians. - High Integration Costs

Traditional palletizing systems require extensive assembly and custom engineering. The Typhon arrives pre-mounted on a robust metal platform, providing plug-and-play deployment and reducing startup costs by up to 80% compared to traditional installs.

Key Benefits of the Titans Typhon Palletizing System

- ✅ High Throughput – Capable of palletizing at speeds of 20 cases per minute (and scalable for higher outputs).

- ✅ Flexibility – Handles a wide range of case sizes from 5”x5”x4” up to 24”x16”x16” with ease.

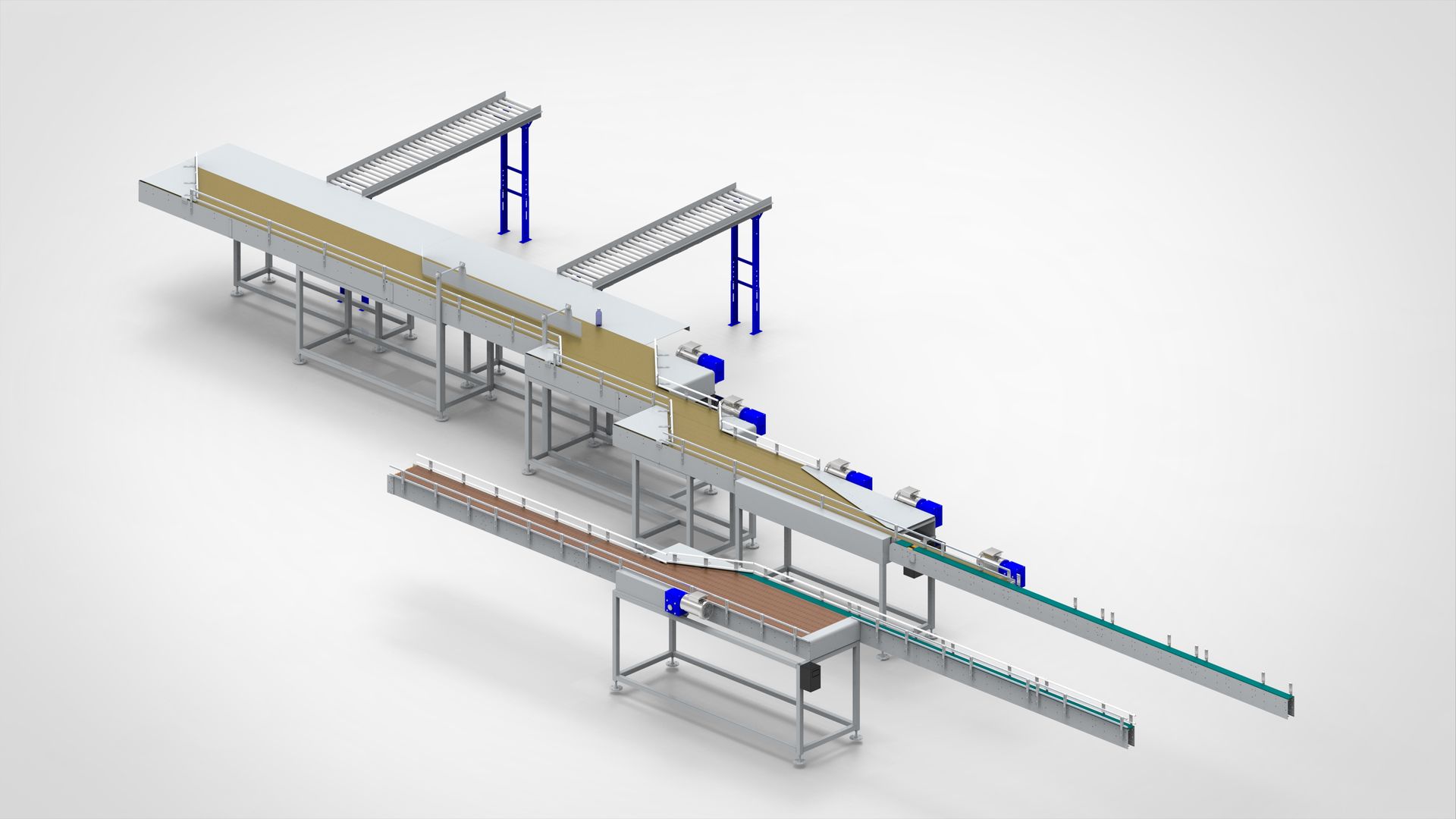

- ✅ Compact Footprint – Space-saving design fits into existing lines without major facility changes.

- ✅ Fast Setup & Quick Ship – Get your system delivered and running in weeks, not months.

- ✅ Autonomy – Integrated software enables your team to adjust pallet patterns without coding or outside support.

- ✅ Durability – Built in the USA with heavy-duty construction for long-term reliability.

Real ROI: What You Can Expect

Let’s break down a Titans Typhon palletizer running 20 cases per minute:

- Labor Savings:

- Manual palletizing typically requires 2 full-time employees per shift.

- At $20/hour, 2 workers cost $40/hour.

- Over a standard 40-hour week, that’s $1,600/week or $83,200/year.

- With 3 shifts, annual labor costs can exceed $249,600/year.

- With a Titans Typhon Palletizer:

- One system replaces those positions, requiring only a single operator to oversee multiple lines.

- Average payback period is 12–18 months (often faster depending on shift coverage).

- Additional Savings:

- Reduced product damage due to consistent palletizing.

- Lower injury claims and absenteeism from heavy lifting tasks.

- Faster shipping preparation thanks to uniform loads.

Result: Most customers see a full ROI within the first year and long-term savings that continue to compound for decades.

Why Choose Titans Packaging?

At Titans Packaging, we don’t just sell palletizers—we deliver complete end-of-line solutions tailored to your production needs. Our Typhon systems are:

- Available with quick ship dates to keep your projects moving.

- Backed by expert installation and support teams.

- Designed for maximum uptime (up to 99% OEE) so your operation never skips a beat.

Take the Next Step

If your production line is still relying on manual palletizing or outdated equipment, now is the time to upgrade. A Titans Typhon Palletizing System will increase your efficiency, cut labor costs, and deliver a measurable ROI in record time.

🚀 Don’t wait for your competitors to automate before you do. Contact Titans Packaging today to request a quote and see how quickly you can transform your end-of-line operations.

📞 Call us now or visit TitansPackaging.com to get started.